Contact us

Add: Benjia Ji, Northern Suburb of Hai'an County, Nantong City, Jiangsu Province, China

Add: Benjia Ji, Northern Suburb of Hai'an County, Nantong City, Jiangsu Province, ChinaTel: +86-513-88755311

+86-513-88755027

Fax: +86-513-88755315

E-mail: dcf@pengfei.com.cn

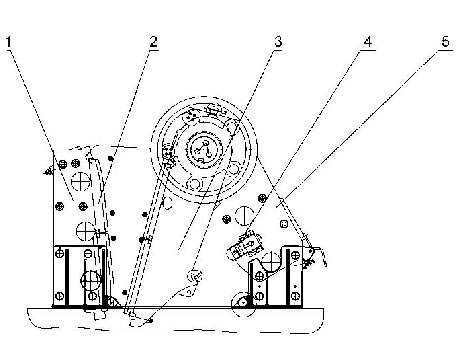

Jaw Crusher

Description of PE/PEX/PEV Series Jaw Crusher:

We have three different kinds of jaw crusher for customers around the world: PE, PEX and PEV, and they are specially used in coarse and medium crushing of ores whose compressive strength is no more than 320Mpa.

The main components of our PE/PEX/PEV jaw crusher include crusher frame, movable jaw plate, movable jaw plate, movable jaw, eccentric shaft, lining plate, and adjustment seat.

Our jaw crusher has features of big crushing ratio, simple structure, reliable performance, easy maintenance, and low operation costs. And its products have even granularity. It is widely used in various fields, such as mining sector, smelting field, building material industry, highway field, railway sector, water conservancy field, chemical industry, and more.

The working principles are as follows: the electric motor drives the eccentric shaft to rotate through the belt pulley, and then the movable jaw will approach or leave the fixed jaw periodically. In this way, the material inside can be crushed progressively smaller and smaller as it travels downward until it is small enough to escape from the bottom outlet.

Technical Parameters of PE/PEX/PEV Jaw Crusher:

| Model |

Max. Feeding Grain Size (mm) |

Adjusted Scope of Nesting (mm) |

Processing Capacity (m3/h) |

Motor Power (kw) |

Weight (Excluding Motor) (t) |

| PE-60×100 | 45 | 3-10 | 0.2-0.6 | 1.1 | 0.16 |

| PE-150×250 | 125 | 10-40 | 0.6-3 | 5.5 | 0.81 |

| PE-250×400 | 210 | 20-80 | 3-13.1 | 15 | 2.8 |

| PE-250×500 | 210 | 20-80 | 5.7-31 | 18.5 | 3.37 |

| PE-400×600 | 340 | 40-100 | 10-40 | 30 | 6.5 |

| PE-430×600 | 400 | 90-140 | 35-60 | 37 | 6.5 |

| PE-475×1050 | 400 | 90-140 | 37.5-81 | 55 | 11.7 |

| PE-500×750 | 425 | 50-100 | 28.5-62.5 | 55 | 10.3 |

| PE-550×900 | 450 | 50-120 | 47-75 | 55 | 7.8 |

| PE-600×750 | 500 | 150-200 | 50-100 | 55 | 12 |

| PE-600×900 | 500 | 65-160 | 30-75 | 55-75 | 15.5 |

| PE-620×900 | 500 | 95-145 | 31-70 | 55-75 | 14.3 |

| PE-670×900 | 520 | 195-245 | 66-83 | 55-75 | 14.8 |

| PE-720×900 | 520 | 195-245 | 66-83 | 55-75 | 14.8 |

| PE-750×1060 | 630 | 80-140 | 72-130 | 110 | 29.3 |

| PE-800×1060 | 640 | 100-200 | 85-143 | 110 | 30 |

| PE-870×1060 | 660 | 200-260 | 181-210 | 110 | 30.5 |

| PE-900×1060 | 685 | 230-290 | 100-250 | 110 | 31 |

| PE-900×1200 | 750 | 95-165 | 87-164 | 110 | 50 |

| PE-1000×1200 | 850 | 195-265 | 197-214 | 110 | 50.6 |

| PE-1100×800 | 650 | 50-125 | 38-156 | 132 | 19.86 |

| PE-1200×1500 | 1000 | 150-300 | 250-500 | 220 | 82.3 |

| PE-1500×1800 | 1200 | 220-350 | 281-625 | 280 | 122 |

| PE1600×2100 | 1250 | 175-300 | 870-1500 | 355 | 169 |

| PEV-430×650 | 360 | 40-100 | 25-75 | 37 | 5.1 |

| PEV-500×900 | 425 | 50-100 | 31.25-68.75 | 55 | 10 |

| PEV-600×900 | 500 | 70-130 | 53-106 | 75 | 13 |

| PEV-750×1060 | 630 | 80-140 | 72-140 | 110 | 24.2 |

| PEX-100×600 | 80 | 7-21 | 2-8 | 7.5 | 0.9 |

| PEX-150×750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-200×1000 | 160 | 20-55 | 6.9-23.8 | 22 | 6.5 |

| PEX-250×750 | 210 | 25-60 | 8-22 | 22 | 5.1 |

| PEX-250×1000 | 210 | 25-60 | 10-32 | 30 | 6.5 |

| PEX-250×1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300×1300 | 250 | 20-90 | 10-65 | 75 | 11.6 |

PEC Series Jaw Crusher

Description of PEC Series Jaw Crusher:

Our PEC series jaw crusher is mainly used to process hard rocks, and it is widely used in quarrying, mining, and recycling of gravels, waste materials and asphalt.

It is designed with innovative modularization frame construction without welding, which ensures this machine good fatigue resistance, perfect reliability, as well as excellent installation diversity. Its high-quality cast steel components and spherical roller bearings ensure its high productivity, high efficiency and low costs.

Features of PEC Series Jaw Crusher:

1. It features high quality, high reliability, no welding structure, repairable crushing frame, and high-quality components.

2. Its operation and installation costs are quite low, and automatic operation and automatic oil lubrication system are available.

3. This series jaw crusher is widely used by fixed and movable equipment.

Technical Parameters of PEC Series Jaw Crusher

| Type |

PEC 80 |

PEC 100 |

PEC 96 |

PEC 106 |

PEC 116 |

PEC 3054 |

PEC 110 |

PEC 125 |

PEC 140 |

PEC 145 |

PEC 160 |

PEC 200 |

|

| Feed opening width (mm) | 800(32) | 1000(40) | 930(7) |

1060 (42) |

1150 (45) |

1375 (54) |

1100 (44) |

1250 (49) |

1400(55) | 1400(55) | 1600(63) |

2000 (79) |

|

| Feed opening depth (mm) | 510(20) | 760(30) | 580(23) |

700 (28) |

800(32) | 760(30) | 850(34) | 950(37) | 1070(42) | 1100(43) | 1200(47) |

1500 (59) |

|

| Motor Power (kw) (HP) | 75(100) | 110(150) | 90(125) |

110 (150) |

132 (175) |

160 (200) |

160 (200) |

160 (200) |

200 (250) |

200 (300) |

250 (350) |

400 (500) |

|

| Motor rotating speed(rpm) | 350 | 260 | 330 | 280 | 260 | 260 | 230 | 220 | 220 | 220 | 220 | 220 | |

| Discharging Size (mm) (in) | Tight-edge discharging mouth size (mm) (in) | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h | t/h |

| 0-30 | 20 | ||||||||||||

| 0-1 1/8 | 3/4 | ||||||||||||

| 0-35 | 25 | ||||||||||||

| 0-1 3/8 | 1 | ||||||||||||

| 0-45 | 30 | ||||||||||||

| 0-1 3/4 | 1 1/8 | ||||||||||||

| 0-60 | 40 | 55-75 | |||||||||||

| 0-2 3/8 | 1 5/8 | 60-80 | |||||||||||

| 0-75 | 50 | 65-95 | |||||||||||

| 0-3 | 2 | 75-100 | |||||||||||

| 0-90 | 60 | 80-110 | 105-135 | ||||||||||

| 0-3 1/2 | 2 3/8 | 90-120 | 115-150 | ||||||||||

| 0-105 | 70 | 95-135 | 125-175 | 125-155 |

150 -185 |

165-205 | 210-270 | 160-220 | |||||

| 0-4 1/8 | 2 3/4 | 110-145 | 140-190 | 135-170 |

160 -205 |

180-225 | 230-295 | 175-240 | |||||

| 0-120 | 80 | 110-150 | 145-200 | 140-180 |

165 -215 |

180-235 | 240-300 | 175-245 | |||||

| 0-4 3/4 | 3 1/8 | 120-160 | 160-215 | 155-200 |

185 -240 |

200-260 | 260-330 | 195-270 | |||||

| 0-135 | 90 | 125-175 | 160-200 | 160-200 |

190 -235 |

205-255 | 260-330 | 190-275 | |||||

| 0-5 3/8 | 3 1/2 | 140-190 | 175-240 | 175-220 |

205 -260 |

225-280 | 285-360 | 215-300 | |||||

| 0-150 | 100 | 140-190 | 180-250 | 175-225 |

205 -265 |

255-285 | 285-365 | 215-295 | 245-335 | ||||

| 0-6 | 4 | 150-210 | 200-275 | 195-250 |

230 -295 |

245-315 | 315-400 | 235-325 | 270-370 | ||||

| 0-185 | 125 | 175-245 | 220-310 | 220-280 |

255 -325 |

270-345 | 345-435 | 260-360 | 295-405 | 325-445 | 335-465 | ||

| 0-7 | 5 | 195-270 | 245-340 | 240-310 |

280 -360 |

295-380 | 375-480 | 285-395 | 325-445 | 355-490 | 370-510 | ||

| 0-225 | 150 | 210-290 | 265-365 | 265-335 |

305 -385 |

320-405 | 405-515 | 310-430 | 345-475 | 380-530 | 395-510 | 430-610 | |

| 0-9 | 6 | 230-320 | 290-400 | 290-370 |

335 -428 |

350-450 | 445-565 | 340-470 | 380-525 | 420-580 | 435-600 | 475-670 | |

| 0-260 | 175 | 24-335 | 310-430 | 310-390 | 355-450 | 370-465 | 465-595 | 350-490 | 395-545 | 435-605 | 455-625 | 495-695 | 630-890 |

| 0-10 | 7 | 270-370 | 340-470 | 340-430 | 390-495 | 405-515 | 515-650 | 390-540 | 435-600 | 480-665 | 500-690 | 545-765 | 695-980 |

| 0-300 | 200 | 335-490 | 395-500 | 410-520 | 530-670 | 405-555 | 445-615 | 495-685 | 510-710 | 560-790 | 710-1000 | ||

| 0-12 | 8 | 390-535 | 445-560 | 460-580 | 580-740 | 445-610 | 490-675 | 545-750 | 565-780 | 615-870 | 780-1100 | ||

| 0-340 | 225 | 495-685 | 550-760 | 570-790 | 625-880 | 785-1105 | |||||||

| 0-13 | 9 | 545-750 | 605-835 | 630-870 | 685-965 | 860-1215 | |||||||

| 0-375 | 250 | 545-755 | 610-840 | 630-870 | 685-965 | 865-1215 | |||||||

| 0-15 | 10 | 600-830 | 670-925 | 695-960 | 755-1060 | 950-1340 | |||||||

| 0-410 | 275 | 690-950 | 745-1055 | 940-1320 | |||||||||

| 0-16 | 11 | , | 760-1045 | 820-1160 | 1030-1455 | ||||||||

| 0-450 | 300 | 815-1145 | 1015-1435 | ||||||||||

| 0-18 | 12 | 895-1260 | 1120-1575 | ||||||||||